RSP Lift-up Method

Applying reinforcement to railway viaducts has many issues due to various restrictions because some of the space under viaducts is also used for public facilities or shops, which remain in use during anti-seismic reinforcement work on the bridge piers.

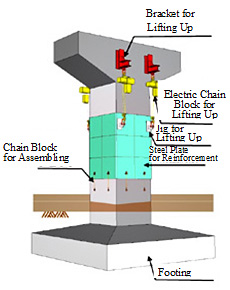

The Reinforcement Steel Plate Lift - up method, which is called the RSP Lift-up method, is a method to wrap reinforcement steel plates around bridge piers by lifting the plates up. In this method, plate reinforcement structures are assembled on the ground and lifted into place. Then, another reinforcement structure is assembled under the top reinforcement structure and also lifted into place. This process is repeated until all the required reinforcement steel plates are installed at their designated locations. The required working space is about half of that needed for conventional methods. This anti-seismic reinforcement work can be applied in narrow working space without demolishing any nearby structures. This reinforcement method has been jointly developed with Tokyu Construction Co. Ltd.

Overview of RSP Lift-up method

RSP Lift-up in progress

Features

- This method can be applied in a working space with a width about 1 m.

- This method has economic benefits because it does not require demolition and reconstruction of nearby existing structures.

- This method can minimize social and business losses to facilities or shops operating under the viaducts because they do not need to be demolished and rebuilt.

- This method is environmentally friendly, with low noise, and provides safety to third parties because large heavy equipment is not required, and only small facilities that can be disassembled are used.

Completed reinforcements with the RSP Lift-up method