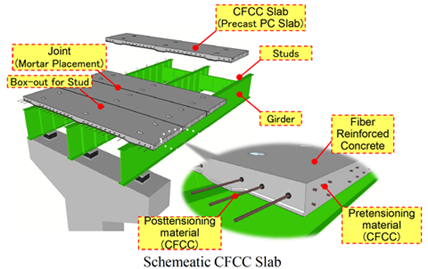

CFCC Slab

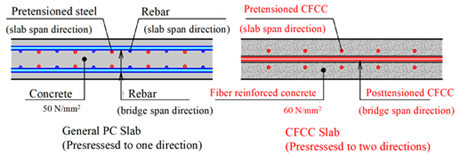

A Carbon Fiber Composite Cable Slab (CFCC Slab) is a precast slab that is formed with prestressed concrete (PC) in both the slab span direction and bridge span direction with a CFCC, which does not corrode. A CFCC is a molded cable that is a mixture of carbon fibers and thermosetting resin. Furthermore, by using fiber-reinforced concrete, the amount of reinforced materials, except for tendons, is reduced and the cost is also reduced.

The CFCC Slab is applicable to Method 3, 'Usage of non-deteriorated materials,' which is intended to ensure durability against salt-induced corrosion, as stipulated in the Specifications for Highway Bridges. The thickness of the covering concrete in a salty environment is not increased because the CFCC Slab is made of corrosion-resistant materials. Posttensioned anchorage devices are usually made of metal even though the posttensioning tendons are CFCCs. The CFCC Slab, however, has non-metal anchorages upon product completion.

From the point of view of long durability and reduced life cycle cost, CFCC Slabs are expected to be used in environments with severe salt exposure, such as the seaside and locations where anti-freezing agents are required, for example, to melt snow and ice.

Features

- The CFCC Slab is applicable to Method 3 to prolong durability, as stipulated in the Specifications of Highway Bridges.

- Increasing the thickness of the covering concrete slab is not required for salty environments.

- A weight reduction of 6%, which is equivalent to 23.0 kN/m3 can be achieved with the same concrete slab thickness.

- The CFCCs can be applied in areas near the box-out of studs for connections between the precast slab and composite girders or areas near catch-basins, where deterioration may occur due to salt penetration.

- The durability of posttensioning CFCCs can be assured against salt penetration from joints between precast slabs.

- The posttensioning anchorage devices are made with non-metal materials.

- Bending fracture behavior and punching shear capacity is the same as that of PC slabs, which are prestressed in two directions by prestressed steel and rebar.

- Fatigue durability is ensured at 300 times the index value, which is equivalent to a 100-year service life in wheel-load-running fatigue tests.