Precast PC Square-Shaped Tank

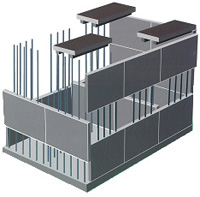

In the construction of a precast prestressed concrete (PC) square tank, precast concrete segments are fabricated at the factory simultaneously, while the tank foundation and slab are constructed on site. After completion of the slab, precast segments of the side walls, inside walls, and roof are assembled on site. It takes about one month from the start of assembly to completion. This method achieves shortened construction time and requires less manpower on site compared with tank construction by pouring concrete in situ. The PC has sufficient earthquake-resistant performance due to prestressed steel bars in the vertical direction and prestressed steel strands in the horizontal direction. Complete liquid tightness is secured between joints of the precast concrete segments, which is a concern in other precast tanks.

Precast PC Square Tank

Features

- Large-capacity structures can be constructed in narrow spaces because the square shape uses the available area more fully compared with round tanks.

- Fabrication in a factory assures high quality and durability of the precast concrete. The life cycle cost of the tank is reduced due to lower maintenance costs.

- The construction period is significantly shortened compared with construction by in situ concrete pouring.

- Water leaks are not a concern because cracks do not form due to prestressing in both the vertical and horizontal directions.

- This construction method realizes low noise and is environmentally friendly.

Erection of precast concrete segment

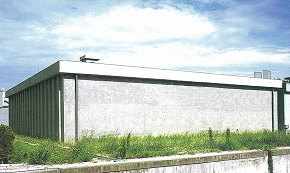

Tank for city water (1,600 tons)

Tanks for city water (3,000 and 2,000 tons)