New Developed Technologies

SI Pneuma

Oriental Shiraishi Corporation, hereafter 'ORSC,' has developed totally unmanned technology that can determine a reasonable design of pneumatic caisson structure and operate construction equipment while considering safety and the environment by maximizing the computerized automated design technology, robotics technology, and environmentally conscious technology. We can call it the SI Pneuma method.

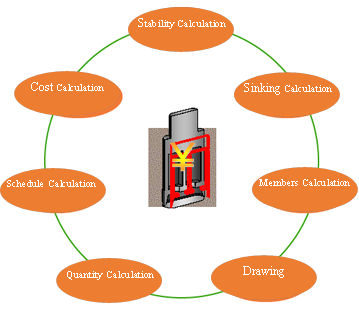

I. Design Technology

ORSC proposed a reasonable pneumatic caisson structural design from design systems like the caisson structural design assistance system, which was developed from various completed caisson projects.

Caisson Structural Design Assistance System

'Performance-based design' requires highly developed skills and various experiences while remaining highly flexible. ORSC meets clients' needs in the performance-based design era by applying our various technologies, such as 'structural analysis technologies' or 'soil analysis and experiment technologies.'

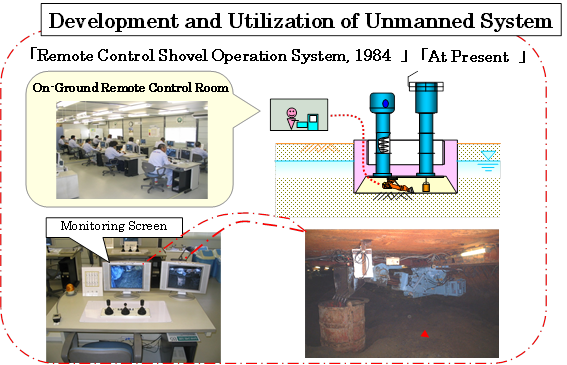

II. Construction Technologies

Remote Control Shovel Operation System

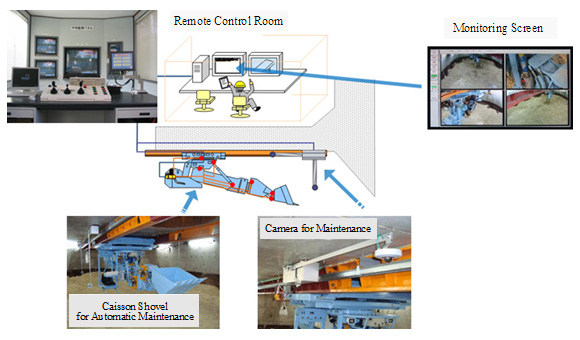

Caisson Shovel Automated Maintenance System

Maintenance of the caisson shovel, such as grease injection, is automated. Abnormal values of various monitoring parameters are detected by an automated maintenance monitoring system that remotely monitors the caisson shovel. By this system, faults in the caisson shovel are detected at an early stage.

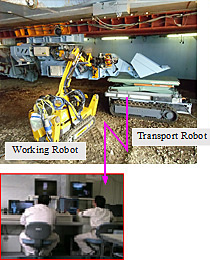

Currently, assembly and de-assembly of the caisson shovel is done by manual labor. In the future, this will be fully unmanned work by a caisson robot remotely controlled from the ground level. The development of this caisson robot is still continuing for higher performance.

Caisson robots under development

The pneumatic caisson construction method has an advantage in testing the load-bearing capacity directly on the supporting ground. In the plate bearing test, the testing equipment can be installed, tested, and removed by the caisson shovel, which is remotely controlled from the ground, and test data can be arranged and evaluated quickly.

Unmanned plate bearing testing system

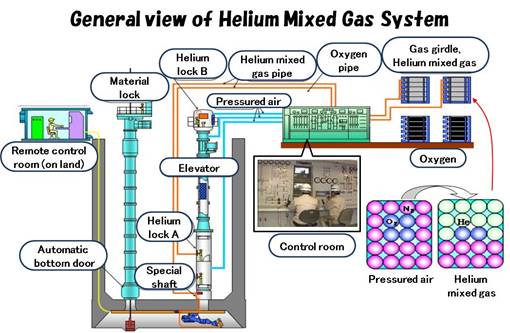

Helium Mixed Gas Respiration System

One of the causes of decompression sickness is the formation of bubbles from nitrogen gas solute in the blood. The helium mixed gas respiration system, which is borrowed from deep water diving technologies, is a mixed gas of helium, oxygen, and nitrogen to reduce nitrogen in the breathing air by adding helium and adjusting the volume of oxygen.

With this system, pneumatic caisson construction can be performed down to 70 m below the water level, or a theoretical working air pressure of up to 0.7 MPa.

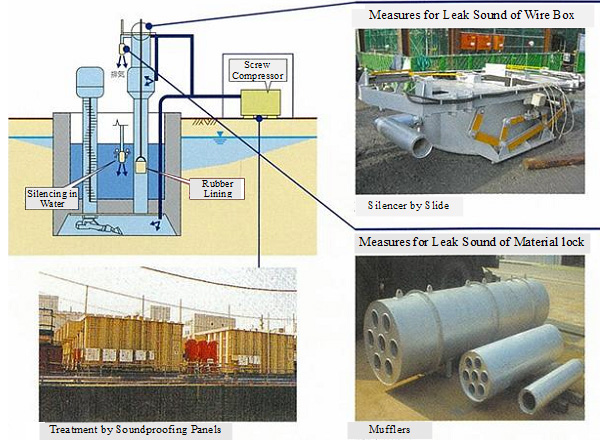

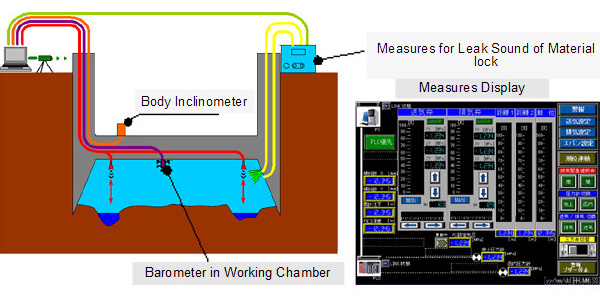

III. Environmental Countermeasure Technologies

Countermeasure Technologies for Noise and Vibration

Overview of System

NETIS Registration No.: KT-990443-V

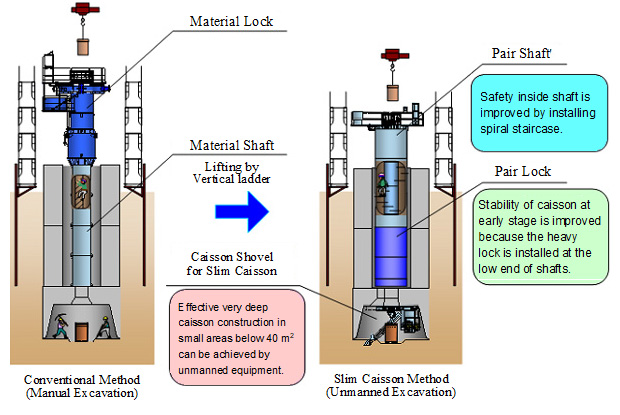

Slim Caisson Method

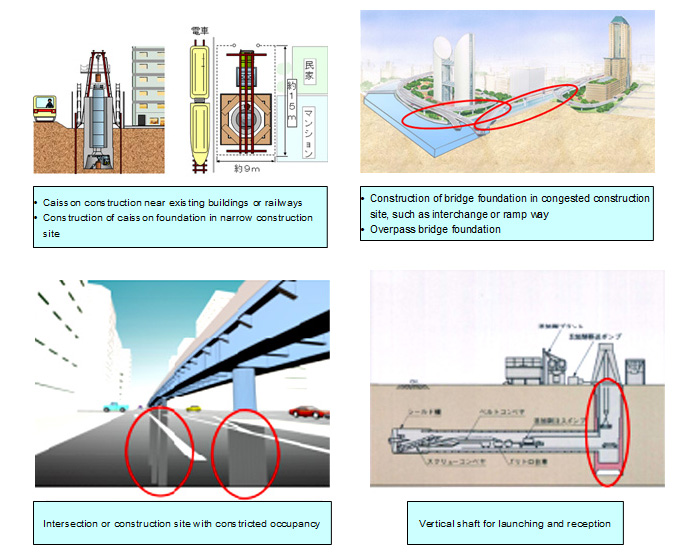

The slim caisson method was developed to be able to excavate with remotely controlled equipment, such as a caisson shovel, in small-diameter caissons below 40 m2. The slim caisson method can be applied to very deep caisson construction up to 0.69 MPa by using an unmanned excavation system and very deep pneumatic caisson construction system. This method is applicable to severely congested construction sites, such as narrow sites, areas with many buildings, or areas with limited overhead space.

Comparison between conventional caisson construction and slim caisson construction

Example applications

Eco Caisson Method

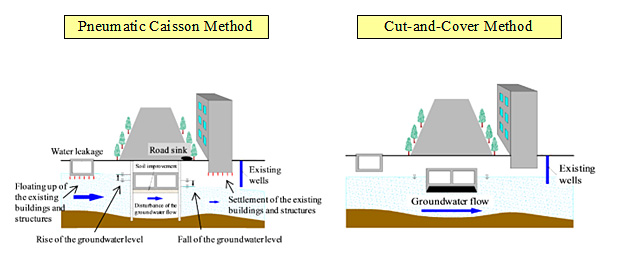

ORSC proposes the 'Eco Caisson' method as a construction method for underground structures where the underground water flow cannot be impeded.

Comparison between conventional construction method and Eco Caisson method

- No structure except the constructed underground structure can interrupt the underground water flow after construction is complete.

- No structure can interrupt the underground water flow during construction.

- The groundwater level cannot change.

- Construction of water collection pipes or water flow pipes in the underground structure can be applied because the underground structure is constructed above ground.

- Underground water flow is conserved when caisson construction is applied at one part of a continuous underground structure.

- Pneumatic caisson construction of a continuous underground structure can be accomplished by installing joints between the structures. In this way, interruption of underground water flow is greatly diminished.

Geo Rifre Caisson Method

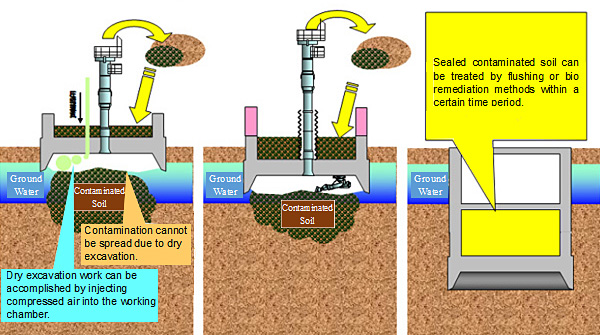

Recently, soil contamination has become an issue due to reconstruction or demolition of factories or hospitals. When the results of soil investigation show contamination over standard values, countermeasures such as treatment or cleanup of contaminated soil should be taken. ORSC proposes the 'Geo Rifre Caisson Method,' which can treat contaminated soil within construction sites by taking advantage of the pneumatic caisson construction method. In other words, contaminated soil can be treated without discharge or treatment outside of construction site.

Treatment of contaminated soil within a construction site by the Geo Rifre Caisson Method